Last Updated on June 6, 2020 by Amit Abhishek

There are different ways to perform the boiler flame failure test. But the most common of them is by taking out the flame eye gently to get an alarm and verify its working.

It is part of the periodic maintenance and checks to verify that all the boiler safety systems are working.

The normal procedure for any boiler is to shutdown and raise the alarm; in event of flame failure. It is a trip that helps prevent the accumulation of fuel into the furnace chamber.

Thus it helps avoid the source of potential explosion when the boiler is fired again. When a flame failure does take place it is the responsibility of operating personal to take immediate actions.

The flame failure trip in a typical boiler can be due to one of the following reasons: loss of ignition; fuel valve closed, unstable flame, low airflow, very high furnace pressure, dirty flame sensor and loss of electrical supply.

It is been seen time and again that a greater number of explosions happen due to do a lack of proper purging or faulty flame sensor.

This is why it is more than vital to test and ensure the working of the flame failure alarm and emergency trip.

Before we get straight into these methods of testing; one must also know “what are flame failure device and how does it work in a marine boiler”.

What Are Flame Failure Device?

A flame failure device or FFD is a safety device used around the world in industrial boilers and burners. It cut off the fuel supply whether gas or fuel oil; thus avoiding hazardous situations.

You can consider it as a safe trip that restricts the flow of fuel to the burner in the event flame goes off unexpectedly.

It is so essential for one’s safety and wellbeing that is considered illegal to operate an industrial or domestic burner without having any form of flame failure device preinstalled.

In contrast, a flame failure device is nothing but a photoelectric diode; one that converts light energy to electrical energy. This again is of different types, for example, I.R or U.V type.

One of the key benefits of a flame failure device is that; your burner is not calling in for fuel without a proper flame.

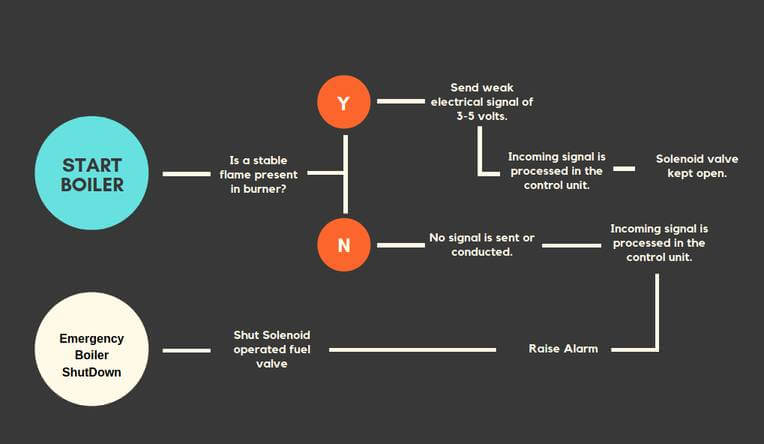

Under normal conditions, the flame sensor detects the presence of a flame and sends electrical signals to the flame detector circuit. This then sends signals to keep the fuel valve open.

In case the sensor did not detect the proper flame for the next 5 to 10 seconds. It raises an alarm and call for an emergency shutdown. The burner can not be ignited only once the trip is reset.

How Does A Flame Detector Work?

There are different types of flame detectors used in burners; of which two are most common: Ionization current flame detector and photocell operated flame detector.

An ionization type flame detector consists of a bimetallic strip or a rod insulated with a ceramic mix. It measures the intensity of ionization by the flame in the form of a weak DC signal.

Now, this weak signal is first amplified and sent to the central controller which operates the fuel valve. Such a type of fire sensor is mostly fitted in household furnace or burners.

Modern industrial and marine boiler utilize different types of flame sensing systems often called “Flame Eye“.

It is an electronic system consisting of a photocell, an electronic controller and a preprogrammed unit. Together they control the air blower, fuel ignition and solenoid operated fuel valve.

For those who do not know or forget what a photocell is? I must tell is a type of resistor that changes its resistance based on the intensity of light falling onto them.

Now in a marine boiler when the intensity of light falling onto these sensors stops or reduces significantly. The conductivity of these resistance stops and thus actuating current to the solenoid stops resulting in the closing of the fuel valve.

Methods To Perform Boiler Flame Failure Test

A boiler flame failure test can be conducted on a ship or industry in three major ways. On one method we simply test the electrical conductivity across the terminals; while on the other two we actually perform a flame failure trip.

In the first method, we need to check for continuity at both ends of the electrodes of a photocell. Make sure it is tested only in the presence of a light source.

Now if the continuity is found it is proved that the flame detector is working properly and there is no need to start and trip the boiler unnecessarily.

In the second method first, fire the boiler normally and let it operate for 1-5 minutes. Then gently take out the flame eye sensor out of the boiler and cover it with a wrap or paper or cloth.

You will notice that within seconds of pulling out the flame eye; an alarm is sound with emergency shut down. This indicates that the flame failure trip is working satisfactorily.

In the third and final method, we first start and run the boiler at high flame. After a few minutes of normal operation, we start to slowly throttle; the fuel valve ( non-solenoid / manual ) to stop position.

You will notice that within a few seconds an alert appears on your boiler control panel followed by the emergency shutdown. This states everything is nice and fine and the test was concluded to be a success.

Also Read:

- Marine Boilers Safety Devices (Alarms and Trips)

- Flame Arrester – It’s Working & Why Is It Required

- Boiler Mountings And Their Function – Complete List

- What are BFP ( Boiler Feed Pump ) – Parts & Working