Last Updated on June 1, 2020 by Amit Abhishek

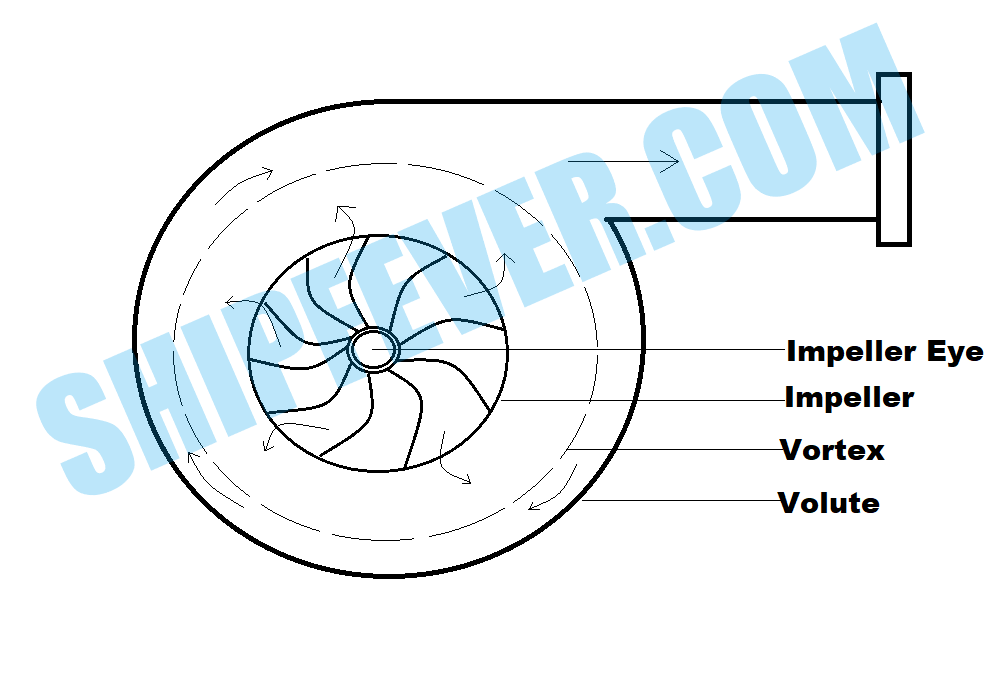

A centrifugal pump is one of the simplest installations of any plant / Engine room. It transfers fluid by the action of the rotation energy of the impeller. This is achieved by converting the kinetic energy of the impeller blades into the pressure energy of the pumped liquid.

Here the energy changes occur under two main parts; the impeller and the volute casing or diffuser. The impeller is the rotating component that converts the shaft rotational energy into kinetic energy.

The stationary parts of the pump, which are diffuser or volute convert kinetic energy to pressure energy.

The efficient operations of the centrifugal pump over time depending upon the sound work of plant managers and maintenance engineers. To regularly inspect and replace parts is the only way to maintain pump efficiency throughout its lifetime.

Routine inspection of bearings, shaft sealing and impeller clearance can help reduce the need for a breakdown maintenance.

Having in-depth knowledge about the common problems and their different deciding factors that may be killing your centrifugal pump performance is a smart thing to do.

- Preventive Maintenance Schedule for Centrifugal Pump

- 10 Common Problems Associated With Centrifugal Pump:

- 1. Pump not developing head nor does it deliver liquid.

- 2. Bearing Overheating

- 3. Bearing operation with noise.

- 4.Bearing having a short life

- 5. Gasket leakage.

- 6. Mechanical seal leakage.

- 7. The pump is consuming too much power.

- 8. Pump operating with noise and vibration.

- 9. The pump is overheating.

- 10. Cavitation

Preventive Maintenance Schedule for Centrifugal Pump

1. Determine Maintenance Frequency

How often should you inspect, repair or do preventive maintenance of your centrifugal pump? What is the best time schedule mentioned by your manufacturer to do preventive maintenance? What was the history of prior maintenance required?

Ask yourself these questions before coming with a suitable maintenance frequency for your centrifugal pump. Consult the manufacturer’s guidelines, past experience and some common sense Determine Maintenance Frequency.

2. Inspect and Replace Mechanical parts

Inspections are done regularly on the ship and in industries. But the frequency of these inspections varies on the different levels of inspections done on the centrifugal pump. Ideally, there are three types of inspection done on any system; routine inspection, quarterly inspections, and annual inspection.

Routine inspection can be done as frequent as required; but generally on a monthly or weekly basis. This involves steps such as checking bearing temperature, pipe lines for leakage, increased vibration, uneven or unnatural noise, mechanical seal, stuffing box, operating current and discharge pressure.

As part of the annual inspection, we check if all mount points are secure, inspect pump flange for leaks, clean filter, inspect coupling, replace mechanical seal, check shaft alignment and replace lubricating oil.

3. Change Lubricating Oil

Changing your pumps lube oil is part of the scheduled maintenance or annual inspection routine. It is somewhat essential to prevent bearing damage. You should always follow the manufacturer guidelines when lubricating the motor.

Make sure you do not under or over lubricate the system. Many a times the damage to the pump is greater in case of over greasing than under greasing; so follow manufacturer instructions. However you might need to replace lube oil more frequent if the pump is used more often in a day.

4. Inspect Electric Motor

One of the key parts of a preventive maintenance schedule for the centrifugal pump is inspecting your electric motors. Check the insulation resistance of connections, ensure all connections are tight and properly secured, inspect motor for the signs of overheating or blocked vents.

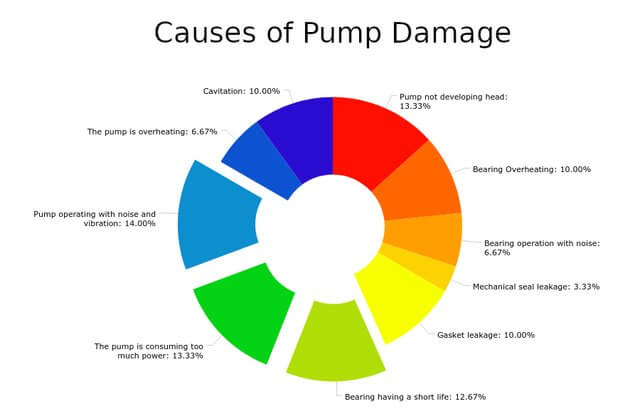

10 Common Problems Associated With Centrifugal Pump:

- Pump not developing head nor does it deliver liquid.

- Bearing Overheating.

- Bearing operation with noise.

- Bearing having a short life.

- Gasket leakage.

- Mechanical seal leakage.

- The pump is consuming too much power.

- Pump operating with noise, vibration.

- Pump is overheating

- Cavitation.

Common Causes For These Popular Centrifugal Pump Problems

1. Pump not developing head nor does it deliver liquid.

- The pump is not primed

- The disengaged or broken connection between the prime mover and pump

- The impeller key is missing or broken. No impeller in the pump.

- The shaft is broken.

2. Bearing Overheating

- Misalignment of pump parts.

- Improper foundation.

- Damaged impeller.

- Bent shaft.

- Inadequate cooling of bearing.

- Inadequate cooling of lubricant.

- Bearing improperly lubricated.

- Water enters into bearing housing.

- Faulty Lubrication system.

- Excessive grease in bearing.

- Damaged bearing housing.

3. Bearing operation with noise.

- If you hear Continuous or intermittent low-pitch tone: Bearing brinelled or resonance with other structural pump parts.

- Steady high-pitch tone. : Misalignment or too much clearance between bearing and shaft or housing.

- Intermittent rattle. : Dirt in bearing or loose machine part.

4.Bearing having a short life

- Misalignment of pump parts.

- Improper foundation.

- Damaged impeller.

- Bent shaft.

- Inadequate cooling of bearing.

- Inadequate cooling of lubricant.

- Bearing improperly lubricated.

- Water enters into bearing housing.

- Faulty Lubrication system.

- Excessive grease in bearing.

- Damaged bearing housing.

5. Gasket leakage.

- Unevenly tightening of bolts

- Uneven thermal expansion.

- Loose bolts

- Too much tightening of the bolt that gasket rubs hard against the shaft.

- Not properly cutting of gasket.

6. Mechanical seal leakage.

- The incorrect type of mechanical seal.

- Bent shaft.

- Dirt in sealing face.

- Sealing face not perpendicular to the pump axis.

- Mechanical seal improperly installed.

- Worn out bearing.

- Mechanical seal has run dry.

- An abrasive particle coming in contact with the seal.

7. The pump is consuming too much power.

- The power measuring instrument is faulty.

- Worn out or damaged bearing.

- Rotating parts rubbing against stationary parts.

- Over-sized impeller.

- Misalignment between pump and drive.

- The mechanical seal is exerting excessive pressure on the seat.

- Bent shaft.

- Impeller or casing partially clogged with solid matter.

- Wrong direction of rotation.

- the liquid is not pre-heated to keep viscosity below specified limits.

- Improper lubrication of bearing.

- Gland too tight.

8. Pump operating with noise and vibration.

- Damaged impeller.

- Wrong direction of rotation.

- Worn-out bearing.

- Impeller improperly mounted

- Air enters the pump during operation.

- The shaft is bent.

- Resonance.

- Improper lubrication of bearing.

- Cavitation in the pipeline.

- The too-small distance between impeller outer diameter and volute casing.

- Loose bolts.

- Damaged bearing.

- Improper foundation.

9. The pump is overheating.

- The pump allowed to run dry.

- Poor lubrication.

- Internal rubbing of rotating parts against stationary parts.

- Damaged bearing.

- Air or vapor pockets inside pumps.

10. Cavitation

Cavitation can occur in two ways for the centrifugal pump; Suction and discharge cavitation. Suction cavitation can be a result of running the centrifugal pump under low pressure for a prolonged period. While discharge cavitation can be the result of running the pump with very high discharge pressure or running it at less than 10% of its BEP (Best efficiency point).

- Choked strainers and filters.

- Poor NPSH (Net positive suction head)

- Wrong pumping design (Pipes and arrangement of pumps).

- Partial blockage in the suction pipe.

- Running too left or right of the normal pump curve.

- Partial blockage on the discharge side.

Also Read:

- A General Overview of Types of Pumps On Ship

- Centrifugal Pumps – Working, Types, Application & Repair

- How To Measure Wear Ring Clearance In Centrifugal Pump

- How To Overhaul Electrical Motors On Ship And Industries