Last Updated on May 26, 2020 by Amit Abhishek

Understanding scavenging requires us to understand why we need scavenging in the first place. We knew that an adequate amount of oxygen is required to start and sustain any combustion. Now since air contains 21% of oxygen; something engine needs in large amounts to burn fuels. Oxygen in the form of fresh air is taken into the combustion chamber to support the combustion process. This method of taking in fresh air while releasing exhaust gas is known as scavenging.

The scavenging process is one of the key factors determining the overall power of the engine; as the poor scavenging process leads to poor combustion. Such poor combustion due to mixing of fresh air with exhaust not just leads to power loss; but adversely affects the engine due to poor running conditions.

Unlike a four-stroke engine where there is sufficient overlap between scavenging and exhaust; two-stroke engines have a limited overlap period to compensate for the compression period.

Consider a two-stroke engine; where the whole combustion occurs within the two-stroke. This leads to a situation where each second of scavenging/exhaust you add each stroke you loose that on compression.

Thus arose the need for an efficient scavenging process to compensate such loss. This is one of the reasons why most high power engines have turbochargers to assist in this process.

Understanding The Complete Process ( Basic Concept )

The process of injecting fresh air to assist the displacement of exhaust gas; out of the combustion chamber is known as scavenging.

For efficient scavenge process, we need proper exhaust; with exhaust valves/port opening before that of scavenge ports/inlet valves.

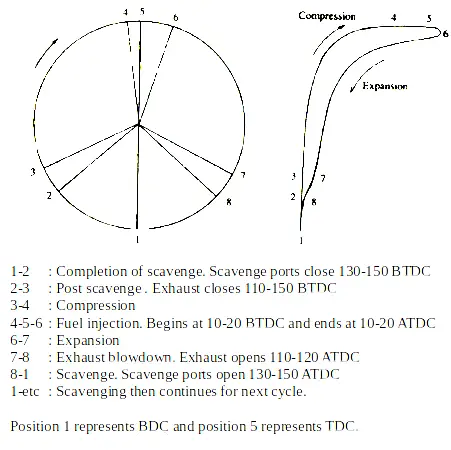

To reduce the loss of fresh air through exhaust outlet; the scavenge port/valve be closed after that of the exhaust valve. We can see this phenomenon for the two-stroke marine diesel engine in the below timing diagram.

Thus, the complete scavenging process can be explained in three main parts; blow-down, scavenge, and post scavenge.

The exhaust starts to move out of the system with the opening of exhaust valve/ports at 110 – 120 ATDC ( After Top Dead Center ).

The sudden opening of the scavenging port at 130 – 150 ATDC further assist in this process. This fresh air sweeps out the exhaust while filling in the combustion chamber.

Now for sometimes both exhaust and scavenge port is open allowing the free flow of air in and out. At 110 – 150 BTDC ( Before Top Dead Center ) the exhaust valves close; allowing some quick time to accommodate much-needed air till scavenge ports close at 130 – 150 BTDC.

Any deviation of the process from its ideal condition leads to; poor engine efficiency, low power output, poor fuel consumption, high-temperature corrosion, lube oil contamination, and wear of piston rings.

Different Scavenging Process in Two Stroke Engine

There is three main scavenge method used in a two-stroke diesel engine. To better understand its application and working we will consider two stroke marine diesel engines.

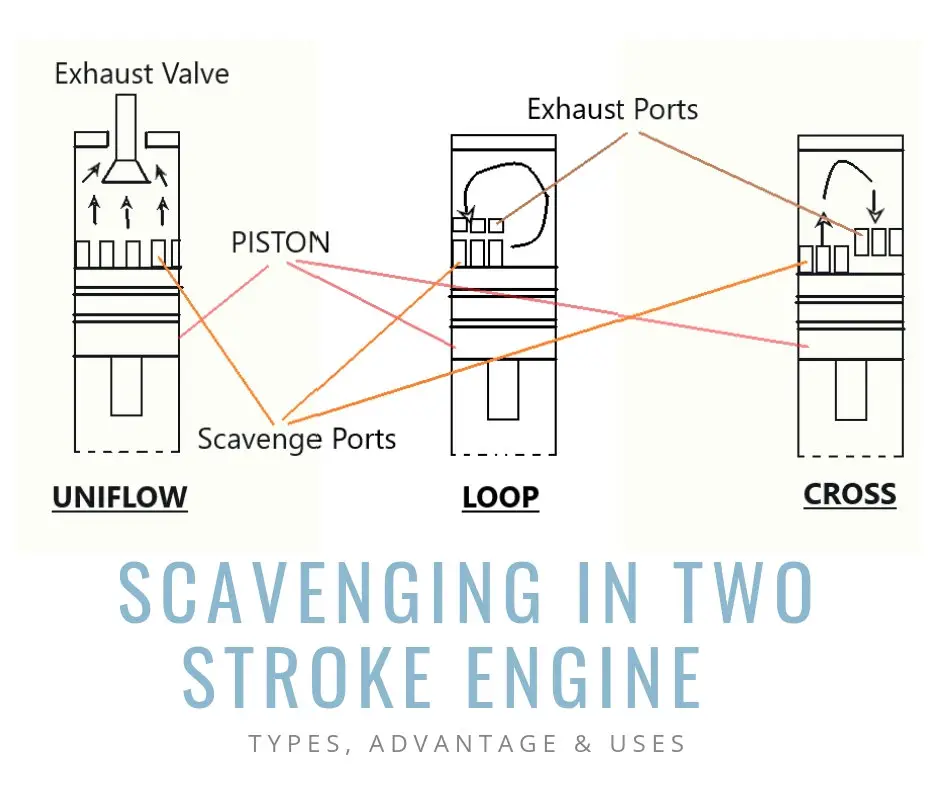

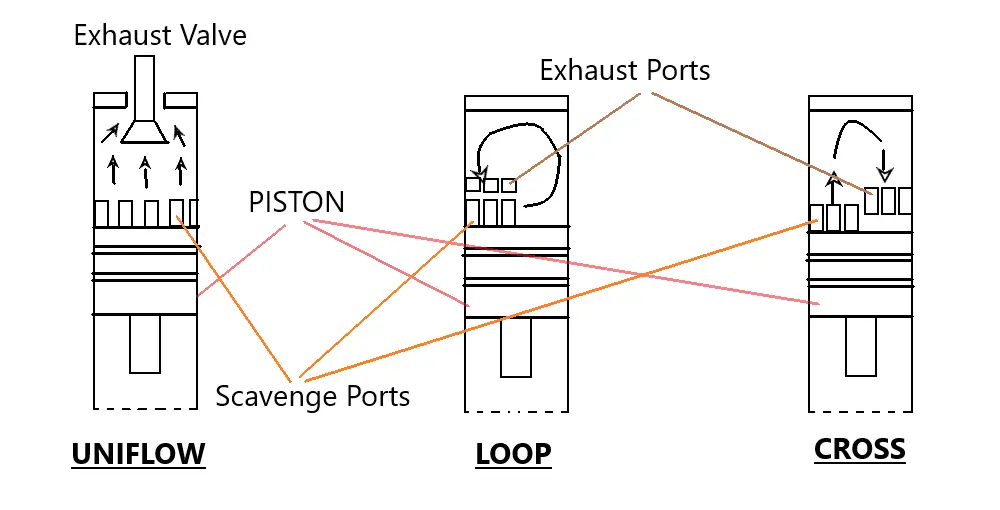

The three main scavenging types are; loop, uniflow, and cross-flow. loop and cross-flow don’t require a dedicated exhaust valve while the uniflow scavenging method does.

1) Loop Scavenging

The diesel engine with no exhaust valve and additional inlet ports; just above the scavenge space are called loop scavenge type engines.

In these engines scavenging takes place with the movement of the piston; with respect to the inlet and exhaust ports on the same side of the liner.

During power stroke ( After Combustion ) piston is forced downwards in the cylinder. The exhaust starts to move out as the piston uncovers the exhaust ports.

With sudden uncovering of the suction ports; the coming fresh air sweeps out the exhaust through the exhaust ports forming a loop inside the cylinder.

The cylinder draws in the more and more fresh air as the piston moves downwards within the cylinder. Then the piston starts to move up; compressing the fresh air in the process.

Soon the suction ports are closed and the engine cope-up with the fresh air; escaping through the exhaust ports for a brief moment till it is covered by the piston.

2) Uniflow Scavenging

Uniflow is the typical scavenging method found in most modern marine diesel engines. It is one of the scavenging methods which does not depends just upon the piston movement.

They consist of an exhaust valve mounted at the center of the cylinder head regulating the scavenging process.

The exhaust valve opens when the piston starts to move down just after the combustion. This helps in releasing exhaust gas outward due to the combustion process.

Now as the scavenge ports are uncovered the fresh air starts to fill in; sweeping exhaust gas outwards through the exhaust valves.

These engines have their scavenge ports are designed at an angle which results in swirling action. This swirling action of fresh air helps in proper atomization as it helps in the improved air-fuel mixture.

The exhaust valve closes just before the scavenge ports are covered by the piston to allow additional fresh air to sweep in.

Although this uniflow scavenging method has relatively more moving parts and is costly; but it allows for longer scavenge time improving the overall efficiency of engine.

3) Cross-Flow Scavenging

A cross-flow type of scavenging method is similar to that of loop scavenging. Due to its compact design and low cost it is ideal for a small two-stroke engine; one that used to be in our vehicles.

In this scavenge method both exhaust and scavenge ports are situated; on the opposite side of the liner with exhaust port slightly above the scavenge space. After ignition as the piston move down the cylinder; exhaust port is first uncovered leading to blowdown.

During blowdown exhaust gas above the atmospheric pressure is released to the atmosphere. Now with the scavenge ports uncovered; the incoming fresh air sweeps out the remaining exhaust gas following a cross-flow within the cylinder.

Then as the piston starts to move up and covers the scavenge ports; the engine tries to hold fresh air within the combustion chamber. There is a continuous struggle to hold air for the time; till the exhaust valves are covered by the piston and compression starts.

Pros & Cons

1 ) Loop Scavenge Method

Advantage |

Disadvantage |

1. Reduced Heat Loss Due to Small Volume of Cylinder |

1. Short Scavenge time |

2. No effect of load on Scavenging Efficiency |

2. Poor Scavenging at top corners of the Cylinder |

3. Low Maintenance |

3. Expensive liner Due to Complicated liner Design |

4. Less Number of Moving parts |

4. High thermal Stress Around Ports due to temperature difference. |

5. No Need of Complex Cooling System |

5. Need improved Cylinder Lubrication System |

6. Does Not Require two or More Fuel Injectors To be installed |

2 ) Uniflow Scavenging

Advantage |

Disadvantage |

1. High stroke to Bore Ratio |

1. Require Complex Cooling Arrangement |

2. Increased Power Output |

2. Is Costly |

3. Simple Liner design |

3. Requires More maintenance |

4. Low cost Of Liner |

4. Requires two or more fuel oil to be fitted |

5. Reduced Lube Oil Consumption |

5. Can not be used with very small engines |

6. Increased Scavenge Efficiency |

|

7. Low Fuel Oil Consumption |

3 ) Cross Flow Scavenge Method

Advantages |

Disadvantages |

1. Low cost |

1. Tendency to Knock |

2. Can be used for any size of engine |

2. Increased Piston ring leakage due to Uneven wear |

3. Unaffected by Load in Engine |

3. Complex liner Design |

4. Simple cooling Arrangement |

4. High Lube oil Demand |

5. No need Of exhaust Valve |

5. Inefficient Scavenge Method |

6. Robust and Need less maintenance |

6. High Risk of Exhaust Gas mixing with Fresh Air |

What is Supercharging And How Does It Differ From Scavenging

In a two-stroke diesel engines the movement of the piston is used to release exhaust and suck in much needed fresh air.

In some engines with a uniflow scavenge system; exhaust valves are used to release exhaust gas. But still piston act as the deciding factor to suck in the much-needed amount of air, and then compress it to ignition pressure.

So such engine types in which scavenging depends solely on the atmospheric pressure with fixed air density are called naturally Aspirated engines.

The air density of one such engine is fixed depending upon the volume of the cylinder and scavenge time. But what if we need to generate more power from the same engine?

We knew power is generated in an internal combustion engine by burning fuel. So more fuel is needed to be injected into cylinder by adjusting the fuel injector setting. But for efficient combustion we need to maintain air-fuel ratio; something can’t be achieved for this case using naturally aspirated engines.

to fix this issue we use centrifugal compressors and turbine droved by the crankshaft to pump compressed air into the cylinder.

This method of using a compressor for forced injection of fresh air during scavenging is called supercharging. In a supercharged engine the fresh air is injected into the cylinder above the atmospheric pressure.

A typical supercharger can increase the power of an engine by 40%. Large diesel engines such as marine diesel engines have a similar but different arrangement to pump in compressed air called a turbocharger. A turbocharger is a similar construction which works using the power from the exhaust gas; rather than taking energy directly from the crankshaft.

Also Read:

- Why Does A Ship Float At Sea But Sinks In River?

- Why Do A Fan Have Capacitor ? – Explained

- Boiler Mountings And Their Function – Complete List

- What are BFP ( Boiler Feed Pump ) – Parts & Working

- Gear Pump Design, Basic Principle & Working