Last Updated on June 4, 2020 by Amit Abhishek

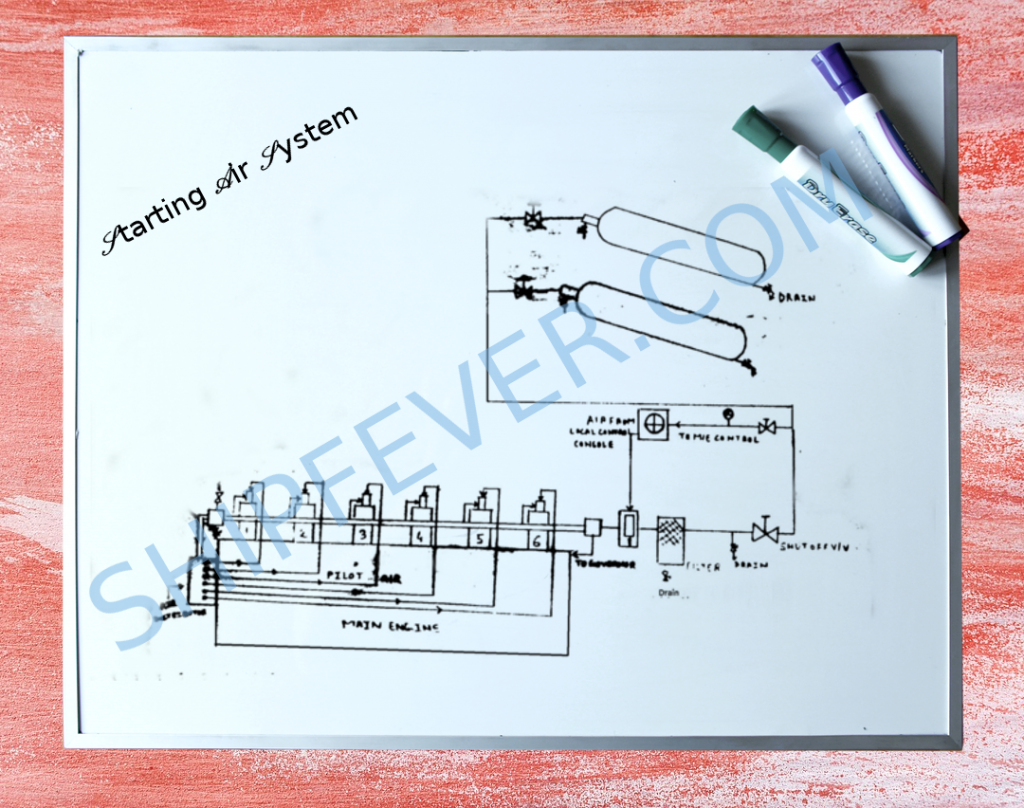

You have heard the term “Air starting system”; but don’t know what it is? Well, the Starting air system uses compressed air to start the main engine. Compressed air is inserted into various cylinders in a proper sequence to provide the initial torque; required to overcome the inertia of reciprocating parts.

Normally, compressed air at 20 to 30 bar pressure is required to start an engine in a certain direction. The compressed air which is inserted into the cylinder is also termed as “starting air”.

This starting air is inserted into a cylinder when it is just past the TDC; and end when the exhaust opens. The pilot valve along with the starting air valve is responsible for the proper injection of starting air timed on the camshaft movement.

Important Parts of Starting Air System

1. Compressors

Today air compressor is used in aerospace, chemical manufacturing, food processing, medical facilities, oil and gas applications, laboratories, dairy, heavy diesel engine, power machinery, panting, breaking system, pneumatic applications control and automation.

It takes air from the atmosphere, compresses it, and then fills up the air bottles to 30 bar pressure. Normally a two-stage air compressor is used on board for this purpose.

A reciprocating air compressor works much like the engine fitted in your car, motorcycle, or any other machinery. It consists of parts such as the piston, connecting rod, crankshaft, valves, and cylinder.

Together they achieve a reciprocating piston assembly that compresses gas by decreasing cylinder volume.

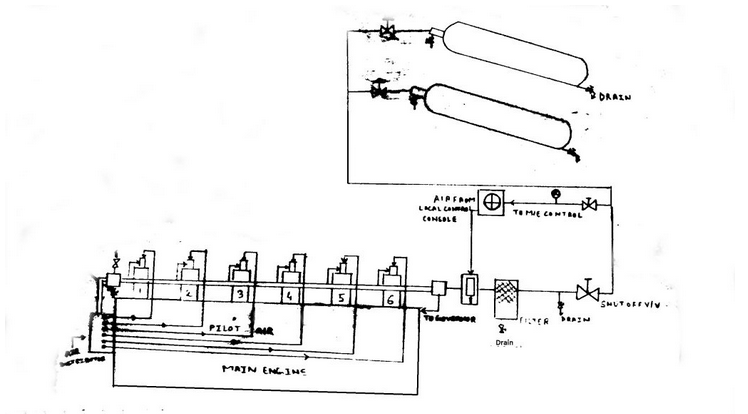

2. Air bottles

The air bottle is a pressure vessel generally made of cast iron used to stored pressurized air output from air compressor. The SOLAS requires ship’s to have at least two identical air bottles at all times. It is these air bottles that supply compressed air for the starting of main and auxiliary engine.

Further, they also supply control and service air for various applications. It has various mounting on its surface in the form of a drain valve, pressure relief valve, fusible plug, spring-loaded safety valve, access doors, and other pressure gauges.

There are two main air bottles in the engine room which stores the compressed air for sudden demand. By law, the air bottles must be of sufficient capacity. Which requires it to store minimum compressed air for twelve consecutive starts for the reversible engine and six starts for the non-reversible engine.

3. Master starting air valve

Master starting air valve / automatic valve is used to connect; or disconnect the supply of compressed air to the engine or starting airline. It ensures that air is available to the starting airline; only for a brief period of time during starting. It also works as a safety device by preventing blow-back to reach the air bottles; Under situation such as cylinder starting air valve stuck in the open position.

4. Starting air valve

It is a valve fitted on the head of the cylinder to allow admission of starting air into the cylinder. Made of mild steel valve body with stainless steel spindle; it operates on the pilot air timed after the camshaft position. The pilot air is admitted in accordance with the engine’s cylinder order.

The starting air valve consist of a valve body, operating piston, closing sping, vent and balancing piston. Under normal condition the valve is shut under spring pressure; but opens when pilot air get admitted from its head pushing the operating piston downwards.

When fully opened it allows the 30 bar air pressure to get injected into the cylinder.

5. Relief valve

Oil particles are always available in the starting air system; thanks to the lube oil of compressors which carried over time to deposit on the walls. Under such conditions, a leaky starting air valve not only reduces the combustion pressure; but also increases the risk for blowback into the starting air system.

Hot combustion gas (blowback) along with oil deposits and compressed air can lead to starting an air-line explosion. So to protect the pipelines from damage; a relief valve is provided to release the extra pressure.

6. Air distributor

The work of air distributor’s in the starting air system is to open the starting air valve by providing pilot air in accordance with the engine’s firing order.

The opening and closing of these valves is controlled using pilot air supplied to them by the starting air distributor. The starting air distributor is the one which ensures; pilot air is supplied to the cylinder as per the proper firing order. Air distributor housing installed in a fixed position; is operated by the movement of camshaft.

The distributor push rods are in contact with the cam assembly and allow pneumatic air signal ( pilot air ) to pass only when; the poppet valves coincide with the correct timing sequence.

A poppet valve is basically located within the distributor housing that avoids distributor pushrods operating individual pilot valve; to make contact with cam when the engine is stopped, operational, or have incorrect timing.

7. Control valve

The control valve operates the master starting valve bypassing control air through it. This allows the main starting air valve to open after checking various interlocks.

Air Starting System Working Principle

A Compressed air of 20 to 30 bar is required to start an engine by providing enough force to turn the engine at speed suitable to reach the combustion temperature and pressure.

There is no set rule for the size of the compressed air cylinder; they should only comply to the rule which states: “There should be enough compressed air to start a reversible engine twelve times in a row and six times for nonreversible type”.

In modern uniflow marine engine the compressed air is injected when the piston is just pass the TDC ( 10 degree before TDC) and close while the exhaust valves going to open ( 5 Degree before the exhaust valve opening).

Steps should be taken to avoid leaky starting air valves; as this can not only increase the temperature of the starting airline but also cause a staring airline explosion. To check for any leakage, simply open starting air automatic valve and air distributor shut.

To start the main engine, control air is given to the control valve which then sends air signals to the automatic valve to open. This leads compress air to the pilot and starting air valve.

Now the pilot valve is under equilibrium by control and starting air at different sides of the piston in the pilot valve. Now the movement of the cam profile leads to the flow of high-pressure air to operating piston of starting air valve.

Which then opens to admit air in cylinder according to the firing order. It will turn engine on air until it reach certain RPM; after that the control air is released from the air control valve. Which then vent the system leading to closure of automatic valve. Then fuel admits the engine and ignition starts.

The above long process would not have taken place if the control valve had detected the turning gear interlock active. A slow turning gear valve is also provided on the system to avoid any water hammering.

Understanding Importance of Overlap in Starting Air System

To ensure starting of marine diesel engine at any position in either direction; starting air is injected in more than one cylinder at a time. This brief period when more than one cylinder is going through starting air operation is called “Overlap”.

An overlap in the starting air system is required to maintain engine momentum by keeping the engine under the condition when a cylinder is at the end of starting air injection while the other is just at the start.

The condition is achieved by controlling the operation of pilot valve under starting air distributor.

Typically the pilot valve is set such that the overlap is about 15 degrees of crank rotation for more than three-cylinder engines. It is so because there is no need for overlap in engine up to three-cylinder as it covers 120 degrees of starting interval for each cylinder. The overlap is only required when the starting interval is less than 105 degrees of rotation.

Precautions

- Regular maintenance should be carried out on the starting air system.

- Be careful, alert and watchful while operating the system.

- Drain’s should be checked at regular interval.

- Engine should never be run while starting air valve stuck or leaking; unless there is an emergency.

- Take immediate actions in case of a fault.

- Do periodic inspection of starting air pipe’s to avoid oil deposition.

Also Read:

- A Guide To Working Principle of Air Compressor

- Starting Air Distributor – Definition, Construction And Working

- How To Start And Reverse The Marine Diesel Engine

- Cylinder Relief Valve: Construction, Working and Overhaul

pilot air at 30 bar opens the airstarting valve,then what does this control air does in the airstarting system?its only about 7 bar

The role of control air in the starting air system is to operate control valve which indirectly operates the opening of automatic valve. Once the automatic valve is opened compressed air at 30 bar pressure is available to the pilot valve and main starting air valve.

i am not clear about pressure range of pilot air and engine starting air is same or various

The operating pressure for both pilot air and main starting air valve is 30 bar. It is just the movement of pilot valve follower to the cam is done by the service air i.e 7 bar initially when the engine is in stop position.

Compressed air inserted into cylinder, is it for pushing the piston down until the self suction of air starts …or just for the combustion inside cylinder which starts the engine? I am confused, please help me out

To explain you in short and simple way; compressed air is inserted inside the engine to ensure the engine gain certain required RPM before the fuel is injected and combustion start.